As energy efficiency becomes more important in modern electronics, resonant power conversion is becoming a prominent technique for minimizing energy loss in power electronics applications. The resonant inductor is an important component in resonant power conversion systems.

The importance of resonant inductors in these systems and their application in zero voltage switching (ZVS) technology, which is extensively employed in power controllers, will be discussed in this article.

What Is Zero Voltage Switching?

Power switches are turned on and off when the voltage across them is zero or close to zero using zero voltage switching. This reduces switching losses and improves efficiency, particularly in high-frequency applications. To reduce the energy losses associated with switching transients, ZVS is extensively utilized in many power conversion systems, including resonant converters.

Resonant Power Conversion

Resonant power conversion systems are designed to achieve high efficiency and minimal switching losses by utilizing the inherent oscillation of circuit parts such as inductors and capacitors. Working in intricate concert with other components, the resonant inductor plays a fundamental role within these circuits, creating an active tank that determines both system frequency and performance parameters.

Resonant Inductors in ZVS Applications

Resonant inductors are key elements in ZVS applications, as they act like a buffer that stores and releases energy based on an established pattern to generate the requisite resonance waveform for clean switching. Though not exclusive to zero voltage switched converters, their inclusion is essential for optimal performance.

By meticulously defining the inductance and quality factor of the inductor, it is possible to adjust the resonant frequency so that maximum performance can be achieved from your power converter. This optimization will guarantee a smooth transition between each switching cycle at its most beneficial point, reducing energy loss significantly.

This type of inductor is especially beneficial for applications operating at frequencies between 20KHz and 1MHz. To get the most efficient operation from a resonant inductor, it should be designed with Litz wire. This reduces copper losses and ensures that current flows evenly through all players of the wire during operation.

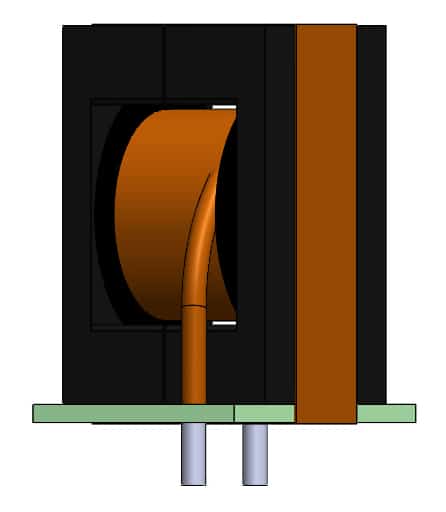

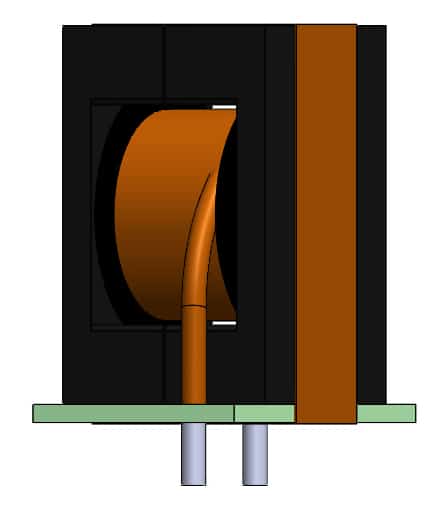

MPS Industries’ ZVS Resonant Inductors

MPS Industries is proud to be a leading provider of reliable and high-performing resonant inductors. Our inductors are the perfect addition to your power conversion system, thanks to their incredible saturation currents, minimal capacitance interference, and low core losses.

When constructing your unique design, MPS Industries’ ZVS resonant inductors come in a range of sizes and inductance values so you can select the most suitable component. Our engineers can help you choose an optimized solution or provide a fully customized design to meet your specific needs. Additionally, these components utilize Litz wire which suppresses skin and proximity effects that may reduce performance when dealing with high frequency applications.

Applications of Resonant Inductors and ZVS

Resonant inductors and ZVS technology are used in a wide range of applications where energy efficiency and high-frequency operation are critical. Among these applications are:

- Power controllers

- Telecommunications equipment

- Electric vehicle chargers

- Data centers

- Renewable energy systems

Conclusion

Resonant inductors are essential components of resonant power conversion systems, allowing for great efficiency and low switching losses. The use of ZVS technology in conjunction with resonant inductors allows for even more energy loss reduction and increased performance in a variety of power electronics applications.

The ZVS resonant inductors from MPS Industries are an excellent example of a component intended to satisfy the demands of modern power conversion systems, delivering dependable and efficient solutions for a wide range of industries and applications.

Dive in!

Learn even more about high current inductors through our resources.